Power Transmission & Distribution

Overcome project obstacles with Almita

|

Industry Specific Challenge |

Almita's Solution |

Staging for Linear Construction of Power Lines |

Unique Installation Equipment Almita’s fleet of track based excavators are perfectly equipped to move down a power line from installation site to installation site. Our depth of powerline construction experience will allow us to help address your project’s specific staging and right of way access needs. |

Uplift Resistance |

Helical Piles In addition to providing excellent compression loading, the helix on Almita’s piles provides superior uplift resistance compared to other foundation solutions. This uplift resistance is critically important to all types of transmission towers. |

Varying Geotechnical Conditions |

Custom Engineering and Field Experience Almita’s team of Engineers has a broad depth of experience dealing with the changing geotechnical conditions that are encountered over the length of a powerline construction project. Our project management team works with you and our engineers to quickly address any challenges encountered in the field, and develop solutions to ensure that your project doesn’t encounter any delays. |

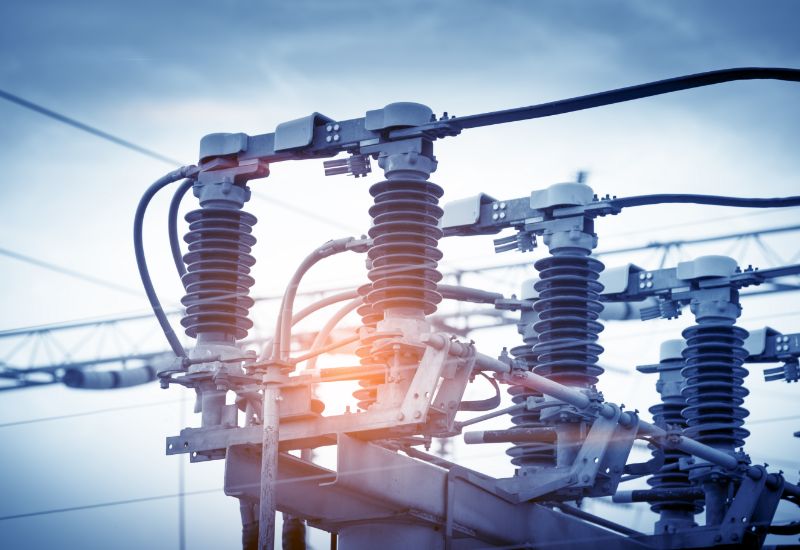

Transformers & Circuit Breakers

Transmission Towers

Telecommunication Towers

Distribution Pole Base

Substations / Inverter Modules

A History of Innovation

Almita can provide Foundation Solutions for any Infrastructure - Large or Small

Since 1991 Almita has adapted product and service offerings to market demands and industry conditions to provide unique and specific engineering solutions for foundation needs. Almita's diverse fleet of custom installation equipment and comprehensive service from planning to installation, we'll put your project and your trust on solid footing.

Design | Manufacturing | Installation | Project Management

We'll save your time, your money and your project

Contact our team today for more information on the products and services Almita provides. We'll help find the best solution for your business, ensuring you get the results you need.